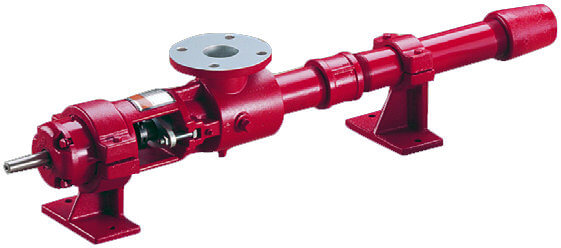

Progressing Cavity Pumps

A progressive cavity pump is a type of positive displacement pump and is also known as a progg cavity pump, eccentric screw pump or cavity pump. It transfers fluid by means of the progress, through the pump, of a sequence of small, fixed shape, discrete cavities, as its rotor is turned.

Roper Pump Company has been manufacturing Progressing Cavity Pumps since 1972, and the time-tested equipment operates in wastewater applications and a broad range of industrial applications: environmental technology, food processing, chemical manufacturing, pulp and paper, and petroleum production to name a few. The advantages of PC technology have made these pumps the favored solution for difficult conveying problems

Among the advantages of a Roper PC pump are:

- Pulsation free pumping

- Application versatility

- High suction lift capabilities

- Flow rates up to 1,000 GPM

- Pressures up to 675 PSI

- Gentle pumping action so that very little shear is imparted to the liquid being pumped

- Ability to handle high viscosity products up to 4,500,000 SSU with or without solids

- Minimal maintenance with wear resistant, hardened and easily replaceable universal joint parts

- Rotors are chrome plated for longer service life on abrasive fluids

- Flows are directly proportional to the speed, for easy pumping control

- Pressure stability over a wide speed range

- Ideal for metering applications

- Stators are available in NBR, Fluoroelastomer, EPDM, HP Rubber, and Natural Rubber. Our HP Rubber resists chunking, and handles temperatures up to 400 deg F.

- Rotors are available in hard chrome-plated hardened alloy steel for maximum abrasion resistance, or hard chrome-plated 316 stainless steel, for corrosion and abrasion resistance.

- Most pumps, and even parts, are interchangeable with Moyno Tarby Liberty Eagle & Continental brands.

All Roper Progressive Cavity Pumps are backed by Roper's expert technical support and customer service dedicated to getting the right pump at an economical price for every application.

All Roper Progressive Cavity Pumps are backed by Roper's expert technical support and customer service dedicated to getting the right pump at an economical price for every application.