|

|

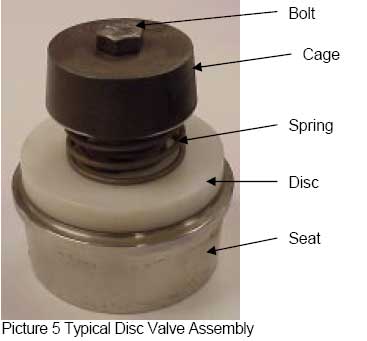

Replacing M14 Disc type Valves |

Introduction

The disc type valve is used in many of the FMC pump models. The standard construction of stainless steel seat, cage and bolt with a Delrin disc are time proven to be a cost effective design with excellent performance and ample life. Other materials of construction including titanium discs and Hasteloy seats are available. A typical valve is shown in Picture 5.

A significant characteristic of the disc valve is the number of webs in the seat. This feature is a factor in determining the maximum allowable discharge pressure of the valve and the methods available to remove them. The valve seat either has three (3) or five (5) webs; see Picture 2 and Picture 3.

When a worn or malfunctioning valve is detected it must be replaced. With disc valves the most difficult task associated with replacing a valve is the removal of the seat from the fluid cylinder. The seats are held into the fluid cylinder with a matching locking taper. Removal is particularly difficult if the discharge pressure of the pump was over 3,000 psi or corrosive fluid was pumped.